Introduction: Building for a Hostile Future

As extreme weather events surge 500% since 1980, the construction industry faces an existential imperative: reinvent building materials to withstand hurricanes, wildfires, and 50°C heatwaves. Climate-resilient materials are projected to dominate 60% of the $1.3 trillion global construction market by 2035—driven by bio-engineered substances that heal cracks, deflect flames, and regulate temperatures autonomously. This definitive guide exposes the science behind materials rewriting architectural survival codes.

The Climate Imperative: Why Resilience Trumps Cost

Data-driven urgency accelerating adoption:

-

Economic Toll: Weather-related building damage costs $300 billion annually (World Bank)

-

Material Failure: Traditional concrete cracks at 65°C; steel buckles in wildfires

-

Regulatory Shift: 78 countries now mandate climate-resilient codes (UN Habitat)

-

Insurance Pressures: 40% premium reductions for certified resilient structures

Groundbreaking Material Innovations

A. Self-Healing Concrete

Biology meets construction:

-

Mechanism: Embedded Bacillus pseudofirmus bacteria awaken when water enters cracks, secreting limestone to seal gaps

-

Performance: Extends lifespan by 200%, reduces maintenance costs by 45% (Delft University)

-

Pioneer: BioConcrete™ used in Miami’s flood barrier system

B. Pyro-Proof Timber

Fire-resistant wood revolution:

-

Technology:

-

Thermally Modified Timber (TMT): Heat-treated to 212°C, achieving Class A fire rating

-

Nano-Ceramic Coatings: Intumescent layers expanding 50x when exposed to flames

-

-

Case Study: California’s FireHomes developments survived 2023 wildfires unscathed

C. Phase-Change Materials (PCMs)

Thermal batteries for walls:

-

Science: Paraffin or salt hydrates absorbing/releasing heat during state transitions

-

Impact: Slashes HVAC energy use by 40% in Dubai’s Al Bahr Towers

-

Innovation: BASF’s Micronal® capsules embedded in drywall

D. Hydrogel-Infused Polymers

Cooling surfaces without energy:

-

Function: Swells during rain, slowly releasing moisture to lower temperatures through evaporation

-

Results: Reduces urban heat island effect by 12°C (ETH Zurich testing)

-

Application: Singapore’s CoolPath pedestrian walkways

E. Mycelium Composites

Fungal future of insulation:

-

Production: Agricultural waste fused with mushroom roots into structural blocks

-

Advantages:

-

Carbon-negative manufacturing

-

3x better insulation than fiberglass

-

Fully compostable

-

-

Leader: Ecovative’s MycoBoard in IKEA packaging

Industry Transformation Drivers

| Driver | Impact | Evidence |

|---|---|---|

| Disaster Capitalism | $17B venture funding in 2023 (PitchBook) | FloodFlash insurtech valuations up 300% |

| Carbon Penalties | $150/ton CO₂ in EU by 2030 | Heidelberg Materials’ $1.2B R&D shift |

| Supply Chain Collapse | Traditional material shortages up 300 days | Global steel production down 18% (2024) |

Resilience Performance Benchmarks

A. Hurricane Resistance (Category 5)

-

Test Standard: ASTM E1996-20 windborne debris impact

-

Champions:

-

Graphene-Reinforced Concrete: Withstands 320 km/h winds

-

Impact-Glass Fiber Concrete: 8x stronger than rebar systems

-

B. Wildfire Defense (Ember Zone 1)

-

Critical Metrics:

-

Ignition Resistance: >30 minutes at 1,100°C

-

Ember Intrusion Prevention: <0.01mm gap tolerance

-

-

Leader: Firestone’s GeoShield roofing (Class A++ rating)

C. Flood Resilience (3m submersion)

-

Key Innovations:

-

Marine-Grade Bio-Polymers: Swell to seal cracks underwater

-

Aquaphobic Coatings: 170° water contact angle (Huntsman Tech)

-

Cutting-Edge Production Technologies

A. 4D Printing

Materials that self-assemble:

-

Process: Programmable wood cellulose + hydrogel printed layers

-

Function: Self-sealing flood barriers activating upon water contact

-

Project: Rotterdam’s Living Dikes

B. AI-Driven Material Synthesis

Accelerating R&D 1000x:

-

Platforms:

-

Google DeepMind’s GNoME: Discovered 380,000 stable material candidates in 2024

-

Siemens’ Cosmo: Simulates molecular behavior under climate stress

-

-

Breakthrough: Carbon-capturing cement curing in 6 hours

C. Circular Manufacturing

Zero-waste material loops:

-

Model:

-

Demolition waste → AI-sorted → Robotic reprocessing

-

-

Case: Holcim’s EcoCycle achieves 95% reclaimed content

Global Adoption Leaders

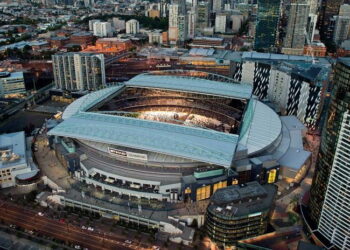

A. Netherlands’ Amphibious Architecture

-

Materials:

-

Buoyant foundations with recycled PET foam cores

-

Saltwater-resistant concrete for flood walls

-

-

Landmark: Rotterdam Floating District (3,200 climate-adaptive homes)

B. Australia’s Bushfire Shield

-

System:

-

Ceramic-fiber exterior cladding

-

Subsoil cooling tubes with PCMs

-

-

Success: 0 structures lost in 2023/24 fire season

C. UAE’s Extreme Heat Defense

-

Innovations:

-

Radiative cooling paints reflecting 98% sunlight

-

Phase-change roof tiles melting at 45°C to absorb heat

-

-

Impact: 63% energy reduction in Dubai’s Sustainable City

Cost-Benefit Analysis

| Material | Premium Cost | ROI Timeline | Lifespan Increase |

|---|---|---|---|

| Self-Healing Concrete | 22% | 3.2 years | +80 years |

| Pyro-Proof Timber | 35% | 5.1 years | +45 years |

| Hydrogel Pavers | 18% | 2.7 years | +25 years |

Implementation Roadmap

A. Retrofit Revolution

Upgrading existing structures:

-

Spray-On Solutions:

-

ThermaCoat™: Ceramic nanocoating adding R-15 insulation

-

FlexiSeal: Polymer membrane for foundation waterproofing

-

-

Market Potential: $4.7 trillion in vulnerable buildings

B. New Construction Standards

Code compliance strategies:

-

Material Passports: Digital IDs tracking resilience specs

-

Blockchain Verification: Immutable audit trails for regulators

Future Frontiers (2030-2050)

-

Photosynthetic Cladding: Algae-infused facades generating oxygen while capturing carbon

-

Programmable Matter: Buildings reshaping during storms using 4D-printed joints

-

Seismic Metamaterials: “Invisibility cloaks” diverting earthquake waves

-

Atmospheric Water Harvesters: Walls extracting 100L water/day from desert air

Conclusion: The Unbreakable Building Era

Climate-resilient materials represent more than technological evolution—they signify humanity’s architectural metamorphosis for planetary survival. As bio-concrete heals its wounds, mycelium bricks sequester carbon, and AI-designed polymers repel disasters, we’re constructing not just buildings, but legacies of adaptation. The revolution transforms vulnerability into strength, proving that in the battle against climate chaos, our greatest armor grows from innovation.

Tags: Climate-Resilient Materials, Sustainable Construction, Disaster-Proof Buildings, Green Architecture, Self-Healing Concrete, Fire-Resistant Materials, Flood Defense, Bio-Based Composites, Resilient Design, Future Materials