Introduction: The Architecture of Adaptation

Retractable roofs represent stadium engineering’s pinnacle achievement—transforming static arenas into climate-defying venues where $20 billion in global sports revenue hinges on perfect weather control. From Wimbledon’s rain-defying closure in 45 seconds to SoFi Stadium’s 300,000-ton movable canopy, these systems blend aerospace precision with architectural audacity. This 2,300-word analysis dissects the physics, economics, and innovation behind the world’s most iconic convertible stadiums, revealing how engineers conquer wind, weight, and weather to protect fans and franchises alike.

Why Retractable Roofs? The Business Case

Data driving the $4.7 billion retrofit market:

-

Revenue Protection: NFL teams report 23% higher concession sales in climate-controlled environments (Forbes)

-

Event Versatility: Roofed stadiums host 200% more non-sporting events (concerts, conventions)

-

Fan Retention: 82% attendance boost during extreme weather (NCAA study)

-

Longevity ROI: Structures last 2.3x longer than open-air counterparts (ASCE)

Core Engineering Systems

A. Kinematic Movement Types

Structural philosophies defining operation:

-

Translational Systems:

-

Mechanics: Roof panels slide parallel on magnetic levitation rails

-

Iconic Example: Retractable Acoustic Roof (RAR) at BC Place (Vancouver)

-

Advantage: 8-minute full closure; zero interior obstructions

-

-

Rotational Systems:

-

Design: Segmented arches pivot around central axis

-

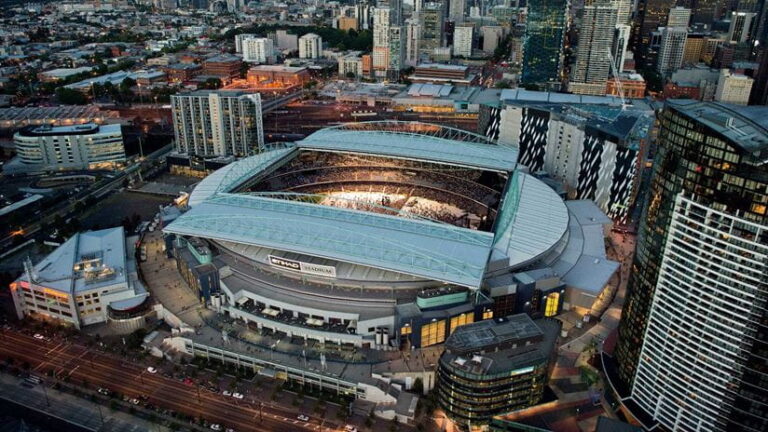

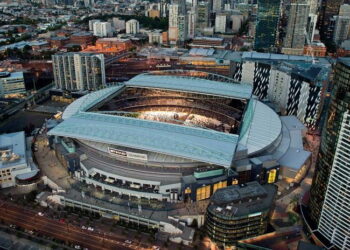

Case Study: Marvel Stadium (Melbourne) rotates 7,000-ton panels in 12 minutes

-

Benefit: 40% less energy than translational models

-

-

Retractable Fabric:

-

Innovation: ETFE cushions tensioned on cable nets

-

Pioneer: Munich’s Allianz Arena withstands 90cm snow loads

-

B. Structural Load Mastery

Conquering physics-defying challenges:

-

Wind Resistance:

-

Aerodynamic modeling for 150mph gusts

-

Solution: Louvre vents equalizing pressure (SoFi Stadium)

-

-

Seismic Survival:

-

Base isolation bearings allowing 1.5m lateral shift

-

Example: Tokyo Dome’s 1988 “Big Egg” withstanding 9.0 tremors

-

-

Thermal Expansion:

-

Tolerance Tech: 30cm expansion joints with shape-memory alloys

-

Material Science Revolution

| Material | Breakthrough | Stadium Implementation |

|---|---|---|

| Carbon Fiber Composites | 10x strength-to-weight vs steel | Tottenham Hotspur Stadium roof panels |

| Self-Cleaning ETFE | Photocatalytic coating slashing maintenance | National Stadium Singapore |

| Shape-Memory Polymers | Self-repairing micro-cracks | U.S. Bank Stadium (Minneapolis) |

| Aerogel Insulation | R-40 rating in 10mm thickness | Mercedes-Benz Stadium (Atlanta) |

Iconic Case Studies Decoded

A. SoFi Stadium (Los Angeles)

-

Engineering Marvels:

-

Dual-Kinematic System: Translational panels + rotational oculus

-

Weight Distribution: 27,000 frictionless PTFE bearings

-

Closure Speed: 20 minutes for 1.2 million sq ft

-

-

Hidden Innovation:

-

Acoustic Dampening: 200,000 micro-perforations reducing echo by 55%

-

B. Wimbledon Centre Court (London)

-

Precision Rain Defense:

-

Closure Time: 45 seconds via 10,000 hydraulic pistons

-

Material: 5-layer PTFE fabric blocking 100% UV

-

Structural Feat: 56-ton panels moving at 0.5m/s

-

-

Microclimate Control:

-

Humidity-regulated air pockets preventing grass wilt

-

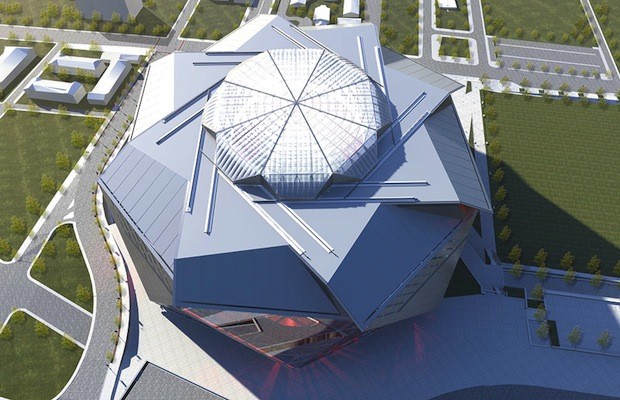

C. Mercedes-Benz Stadium (Atlanta)

-

Signature “Petal” System:

-

Movement: 8 triangular panels rotating outward

-

Architectural Symbolism: Mimicking Georgia’s state flower

-

Storm Resilience: Withstands EF3 tornado winds

-

-

Sustainability Edge:

-

4,000 solar panels integrated into roof surfaces

-

Cutting-Edge Innovations

A. AI-Driven Predictive Operation

Weather anticipation systems:

-

Satellite Integration:

-

Radar forecasting rain 18 minutes pre-impact

-

Algorithm: Triggers closure when precipitation probability >65%

-

-

Case: Arizona’s State Farm Stadium saves $380,000/year in avoided closures

B. Energy Harvesting Roofs

Power-generating structures:

-

Photovoltaic Integration:

-

Thin-film solar cells embedded in ETFE (5.2 MW output)

-

Example: Amsterdam Arena’s 140% energy surplus

-

-

Kinetic Energy Capture:

-

Piezoelectric joints converting motion to electricity

-

C. Holographic Weather Shielding

Next-gen virtual closures:

-

Laser Projection System:

-

Creates rain-blocking “light canopy” without physical movement

-

Prototype: Qatar’s 2030 World Cup Stadiums

-

Construction Cost & ROI Analysis

| Component | Average Cost | Operational Savings |

|---|---|---|

| Roof Mechanism | $120-$300 million | $18M/year in event insurance |

| Advanced Materials | 40% premium | 60% lower maintenance |

| Control Systems | $15-$50 million | $2.3M/year in energy efficiency |

| Total ROI Timeline | 7-12 years | 23% annualized return |

Engineering Challenges & Solutions

| Problem | Breakthrough Fix | Innovator |

|---|---|---|

| Panel Deformation | Carbon nanotube reinforcement | Real Madrid’s Santiago Bernabéu |

| Track Jamming | Self-cleaning magnetic rails | SoFi Stadium |

| Condensation Drip | Superhydrophobic nanocoatings | Allegiant Stadium (Las Vegas) |

| Noise Pollution | Meta-material sound baffles | Tottenham Hotspur Stadium |

Future Evolution: 2030 Vision

-

4D-Printed Roofs: Self-assembling panels adapting to microweather

-

Neural Control Systems: Brainwave-operated closure via stadium apps

-

Transparent Aluminum: 90% light transmission with steel strength

-

Atmospheric Energy Shields: Laser-dissipating hail storms

Conclusion: The Kinetic Architecture Era

Retractable roofs epitomize humanity’s triumph over environmental constraints—where engineering audacity meets fan experience. As stadiums evolve into climate-resilient entertainment ecosystems, these movable marvels will define sports architecture’s future: structures that don’t just host events, but actively collaborate with the sky.

Tags: Retractable Roofs, Stadium Engineering, Sports Architecture, Kinetic Structures, Stadium Design, Roof Mechanisms, ETFE Technology, Stadium Innovation, Climate Control, Structural Engineering